TypicRevealing the Potential of Compressed Earth Blocks—A Study in the Materiality of Compressed Earth Blocks (CEB): Lightness, Tactility, and Formability, by Egyptian architect Omar Rabie, documents explorations of the potential of CEB while studying at MIT, The Architectural Association and Auroville.Interlocking Compressed Earth Block (ICEB) are cement stabilized soil blocks that allow for dry stacked construction. Because of this characteristic.13.10.1.1 Shelled compressed earth press. The conventional compressed earth block presses produce blocks with one material mix.

Compressed Dirt Blocks Full Aesthetic And

On the level of construction, it introduces simple and easily assimilated improvements to a traditional material – stabilised earth – which allow it to achieve its full aesthetic and environmental potential. A compressed earth block, also known as a pressed earth block or a compressed soil block, is a building material made primarily from damp soil compressed at high pressure to form blocks. Compressed earth blocks use a mechanical press to form blocks out of an appropriate mix of fairly dry inorganic subsoil, non-expansive clay and aggregate.

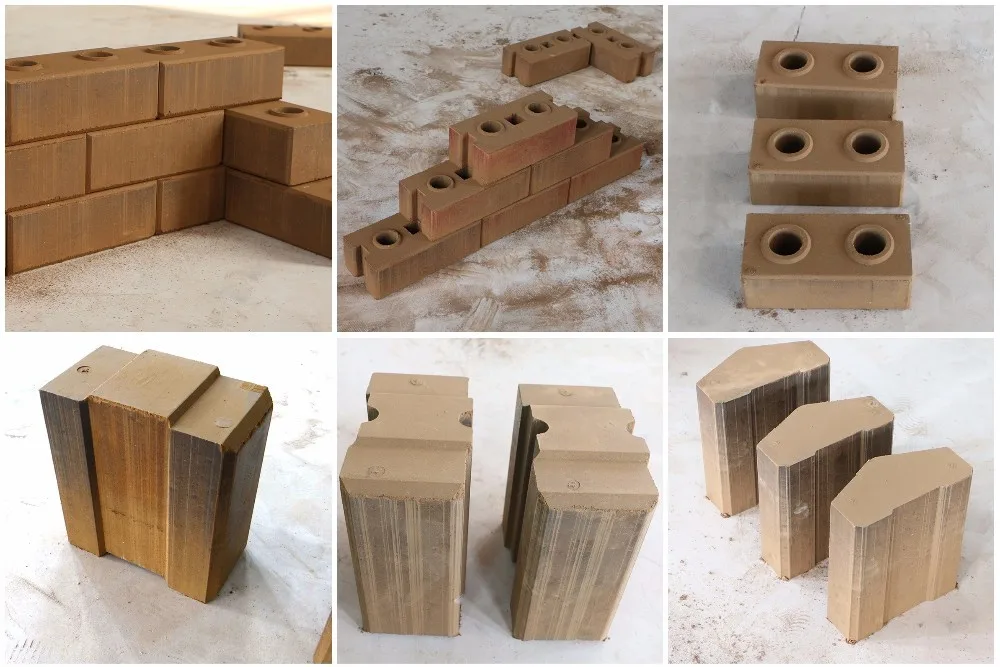

The market was the result of a truly participatory process that brought together and engaged the entire community in the site selection, design and construction of the market as well as its continuing use. A 1:1 prototype of a typical retail space was constructed which helped facilitate communication between the different collaborators, simultaneously allowing refinement of the design, development of innovative construction techniques and practical training of the local masons. 13.6) be designed and fabricated to produce SCEB of two material mixes. A separator with two hoppers was introduced to the main mould to separate the shell from the core.In these two experimental mock-ups, Rabie explored the different possibilities of bondings using one block—specifically how the shape of the single block influences the block bonding patterns in a stack bond and running bond.Climate Control & HVAC Equipment Rentals Compressed Air Equipment & Air Tools Earth Moving Equipment. Silica Dust Safety.This portion of a wall was built of specially formed interlocking blocks to increase friction to test how high friction masonry wall will highly resist lateral loads in comparison to walls constructed with standard blocks. In this case, the blocks are interlocked in the long direction of the wall.

Amongst the problems with papercrete are, mold, shrinkage, and slow drying time. The paper in papercrete is proported to have great effect as a stabilizer. Some sources don't even recommend using stabilizers other than cement even when building in developing countries Paper as a stabilizer Papercrete, a cement and paper building material, has been fairly well researched and tested. Here in the United States, the presence and low cost of cement makes it both physically and economically efficient. They include such wondrous things as plant juices, whey, resins, molasses, wood ashes, and lime just to name a very few. They can be broadly classed into natural and manufactured.

The amount of cement needed will be relational to how close you are to this ideal, ranging from 3-5% to 10%. That said, I am quite happy with the experience and the primary goals, education, experimentation, and repeatability, were satisfactorily met.Sand (sadly, after late game decision against on-site sand =(purchased)Boric Acid(as ortho boric acid from coachroach poison)Preparation Earth calibration After testing your soil, preferably in multiple locations, you will have an earth mix that is about 75% sand and at least 10% clay and less than 35% clay, by volume. Only about three dozen bricks have been made so far.

The sides of the box must be slippery so use an oil if the sides are rough.Preface to Ram operation This is ideally a group activity. This requires a long ish box, think over a foot by 4 inches by four inches. I chose, the 'block test' and 'salt water test'.The block test The block test is simply, to make a block out of your earth and measure the shrinkage.

mixing surface(sheet of plywood, where available, to avoid mixing with cement on ground) I will briefly describe a non-mechanical brick forming method that doesn't require any more than personal conviction, and minimal tools.Materials needed (for non-mechanized mixing) Four people is nice, six people is ideal in my experience.

Now draw a line, up this measured distance from your half way line. Approximate these ticks measure. Repeat this process twice more. Carefully place one of the piles into the bucket, make tiny tick marks around the bucket at height of the soil. This may take a little work, don't try for perfection, do a decent job of it and proceed. Deposit the second bucket on the mixing surface, form one pile, divide this pile into 10 equal piles.

The most successful work group ended up being my engineering 305 class. However, if you are using another stabilizer you will likely have to use twice as much.Now to actually go about making some compressed earth bricks.I attempted to employ the old "workshop = group labor camp" ploy, with limited success. Some documentation points to the possibility of getting the cement percentages as low as two percent. Then again halved between the 5% test line and the 10% line. If you are testing to determine best mix ratio, vary your cement input from 10% to 5% by halving the distance between the 'earth' and the cement lines. This gives you approximately ten percent cement stabilization when measuring.

0 kommentar(er)

0 kommentar(er)